An Orifice Plate is a Differential Pressure Producing Primary Flow Element. It is a metal Plate with the Hole in the Middle for the Fluid to go through it. The Type of Material is determined based on the Temperature as well as the Media that is flowing through the Pipe . Orifice Plates are normally sandwitched in between two Flanges . It is one of the most accepted, efficient and versatile methods of Measuring Flow. When an Orifice Plate is placed in a Line, a Differential Pressure is developed across the Orifice Plate. This Pressure Drop is Linear and is in Direct Proportion to the Flow Rate of the Liquid or Gas. It basically follows the Bernoulii’s Principle which states that there is a relationship between the Pressure of the Fulid and the velocity of the fluid. When the Velocity is increased, the pressure decreases and vice versa.

The Differential Pressure is measured by suitably located pressure tapping on the pipeline on either side of the Orifice Plates. These Taps may be located on Orifice Flanges or Corner Tap Flange or on the Pipe Itself. An Orifice plate has a 4 to 1 Ratio in measurement and its accuracy is +/- 1% of the Flow.

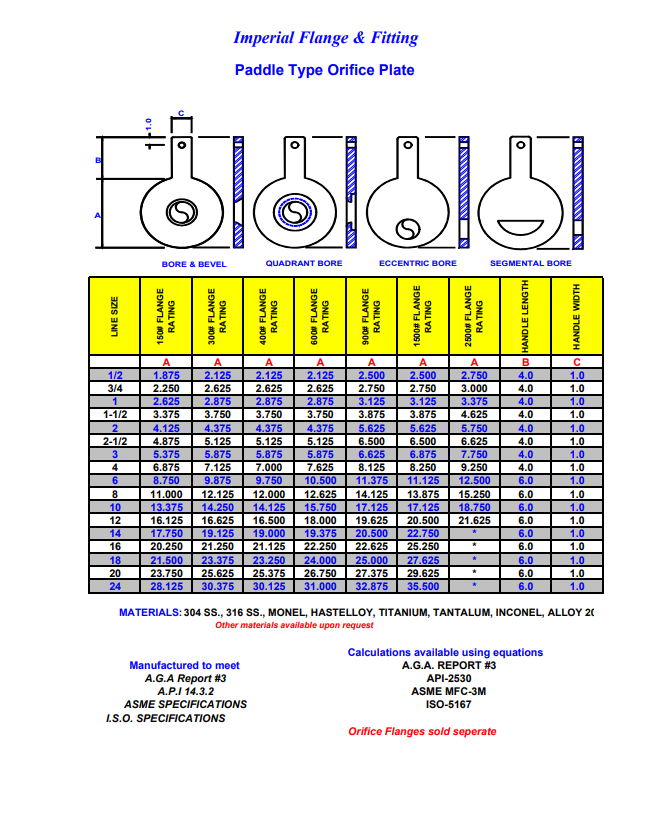

Orifice Plates can also be used in order to reduce the Pressure as well as Regulate the Flow. There are different types Of Orifice Plates such as Concentric, Eccentric, Segmental ,Conical, Integral and Quadrant. Here at Imperial Flange and Fitting we Offer Orifice Plates in 316SS, 304SS, Titanium, Tantalum, Monel, Hast-C , Inconel, Teflon and many other Materials.

Reviews

There are no reviews yet.